#190620 Hand Gear Product Design Consultation

-

March 2019 -June 2019

-

VGO

-

Product/design consultant contract

-

To design a series of performance gloves.

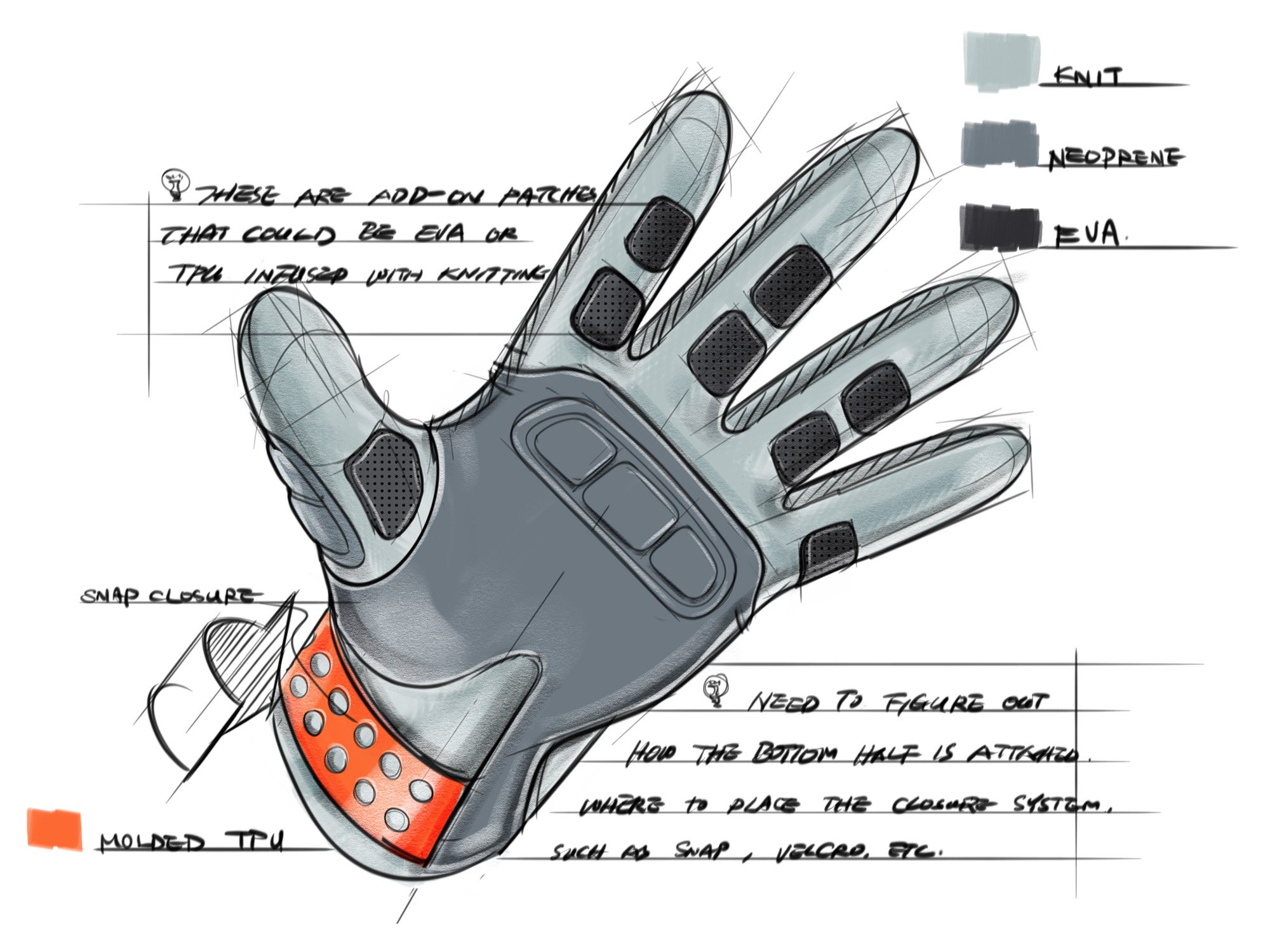

This hand gear/glove project is a product design consultation. The company/brand is a local Chinese hand gear manufacturer. The company is exploring the how to utilizing injection moulding technology on hand gear. (Fact: Direct injection moulding technology on hand gear products is a very rare due to its high cost and limited hand gear demand in the market.)

The company had serval attempts trying to design utilizing this injection technology. I was brought on board with along with a local product marketing team to explore feasible product/design options.

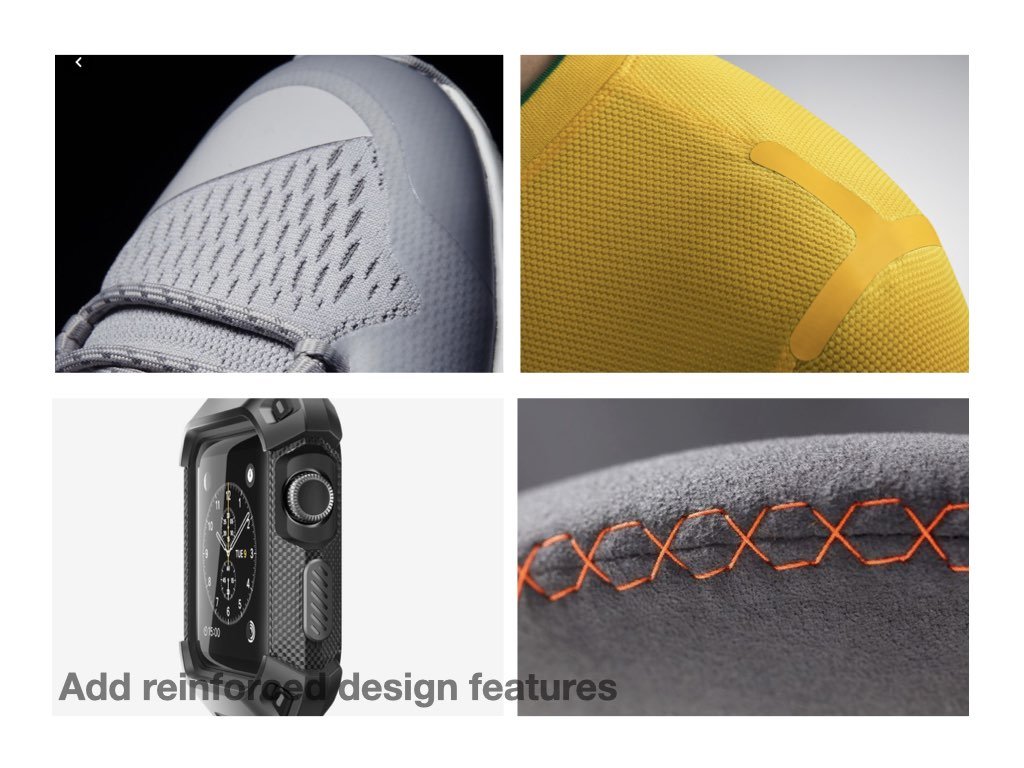

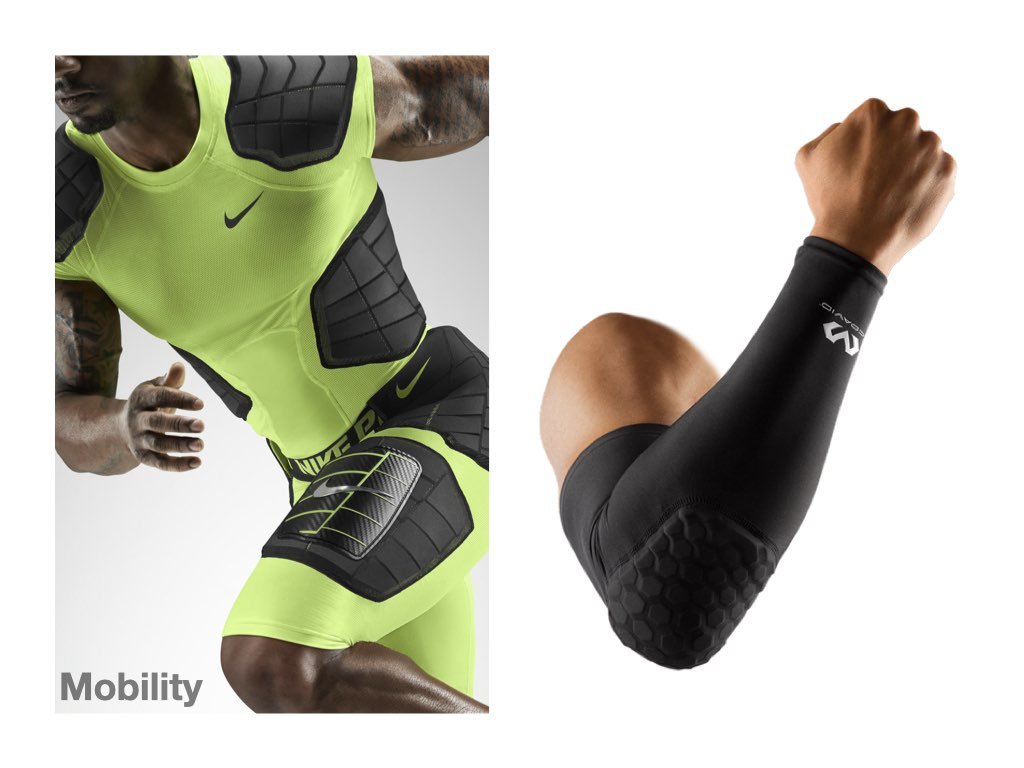

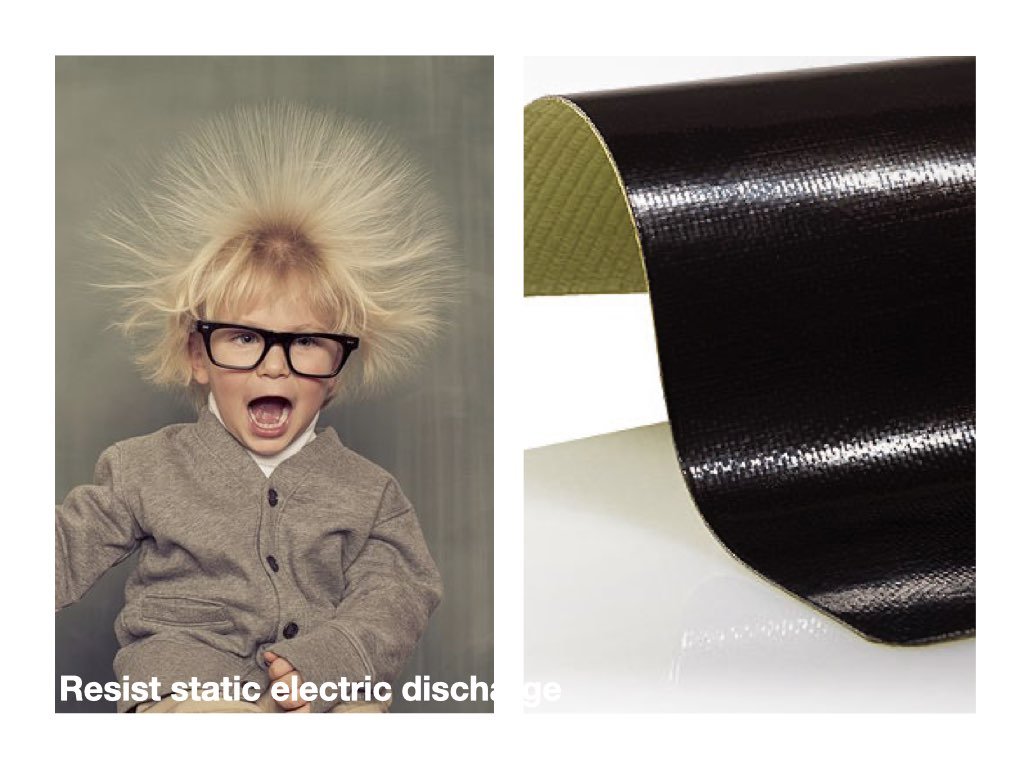

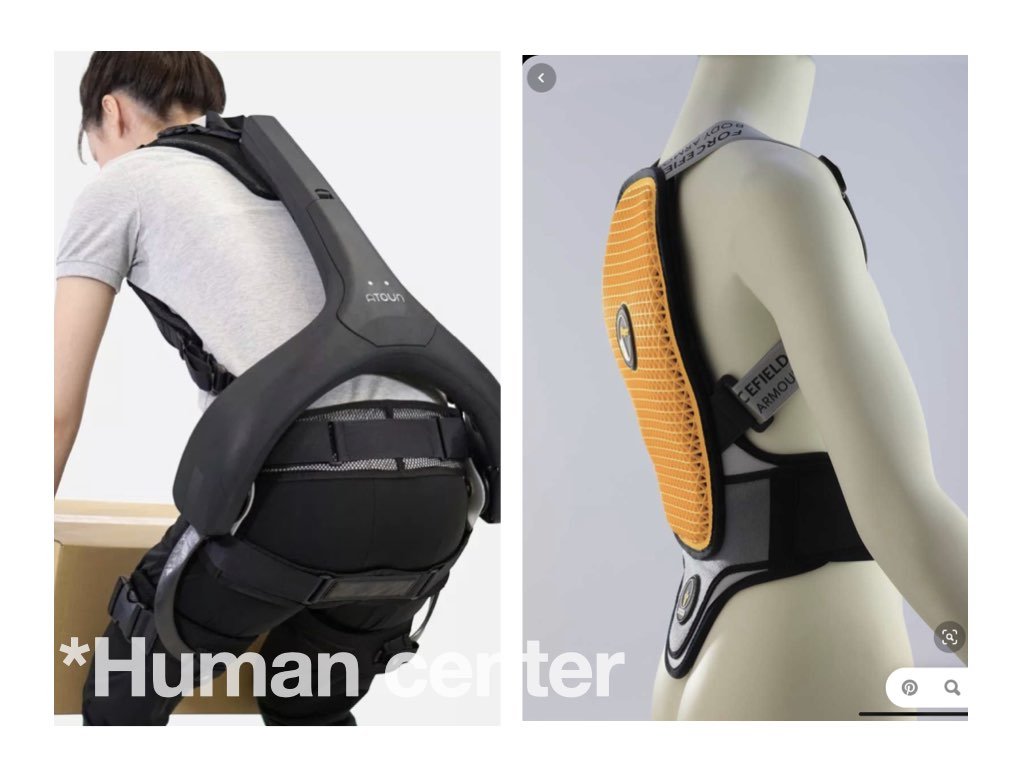

Design Mood board

After the kick-off meeting taken place, I was well aware that the brand has limited resources and experience to truly pull off what they were trying to achieve during this project. The design mood board I was putting together has to consist wide arrange of areas in order to make this a meaningful project that leading to a product that make sense in the end. The design brief mainly focused around function and performance features such as protection, friction, support and flexibility, etc. It also covers the area of breathability, mobility, durability and sustainability.

Product Brief

The product brief is on the other hand a blueprint of what the company’s capacity and resources, which hopefully leading into a feasible product design/execution solution for a new product.

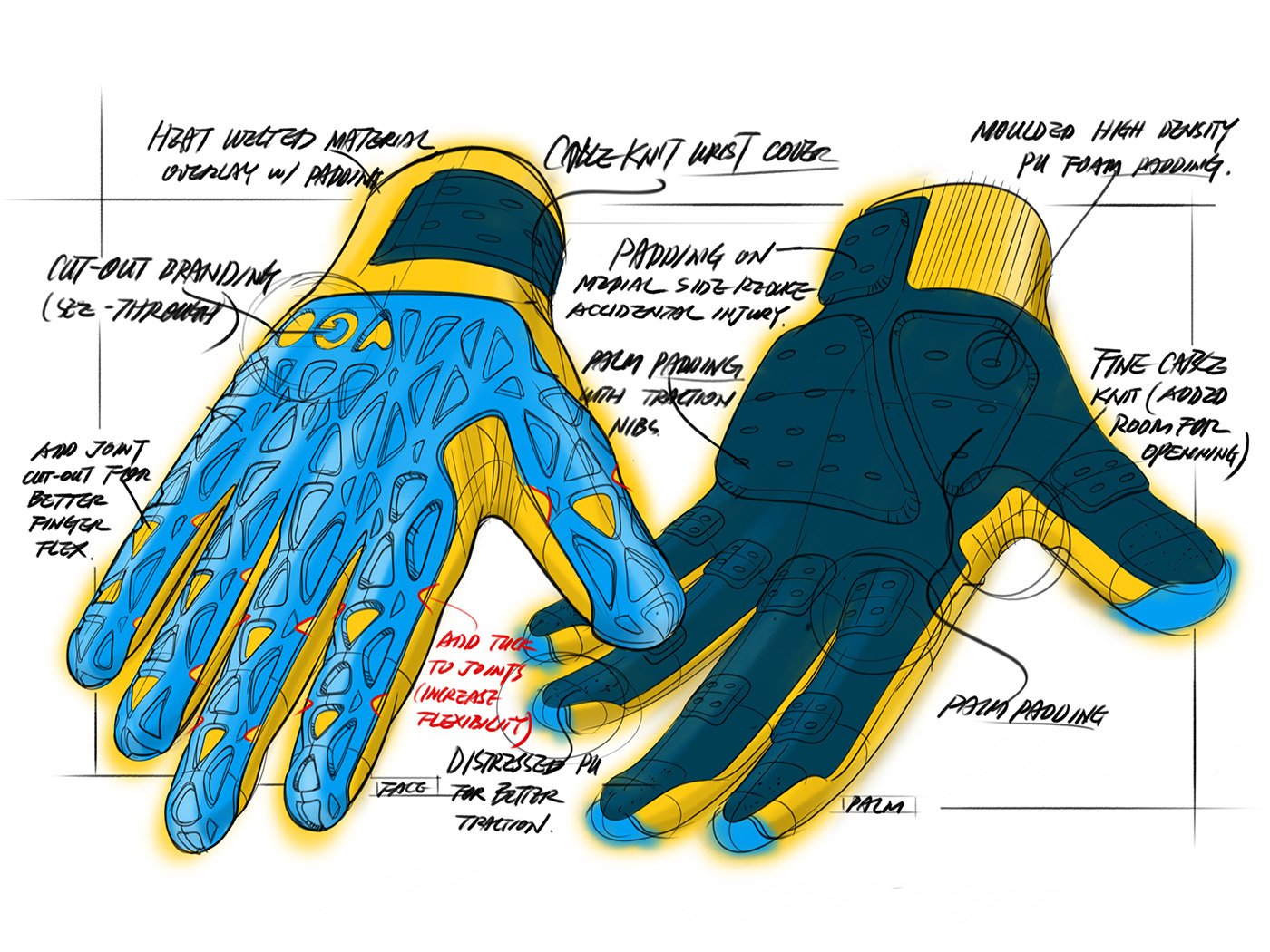

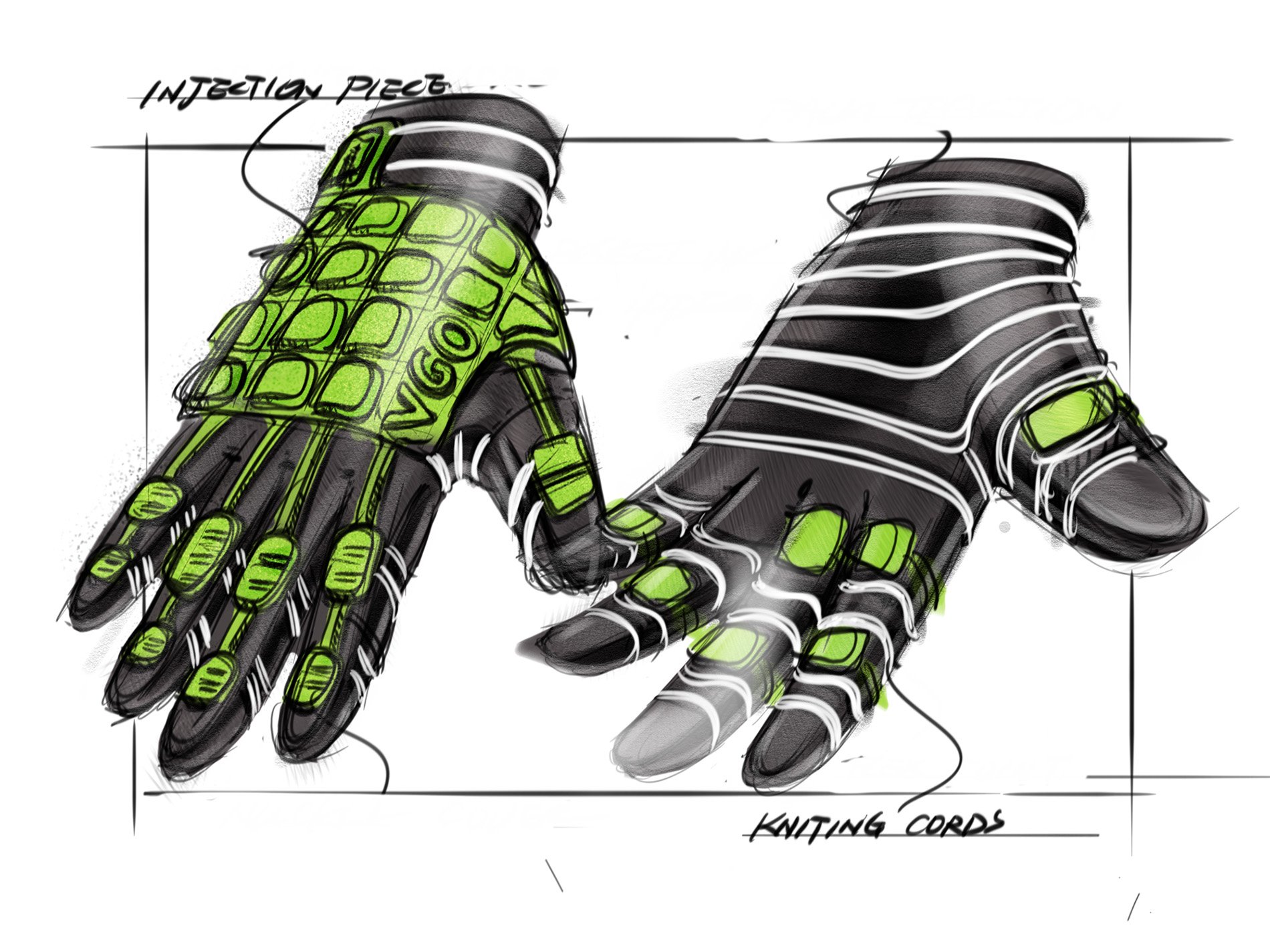

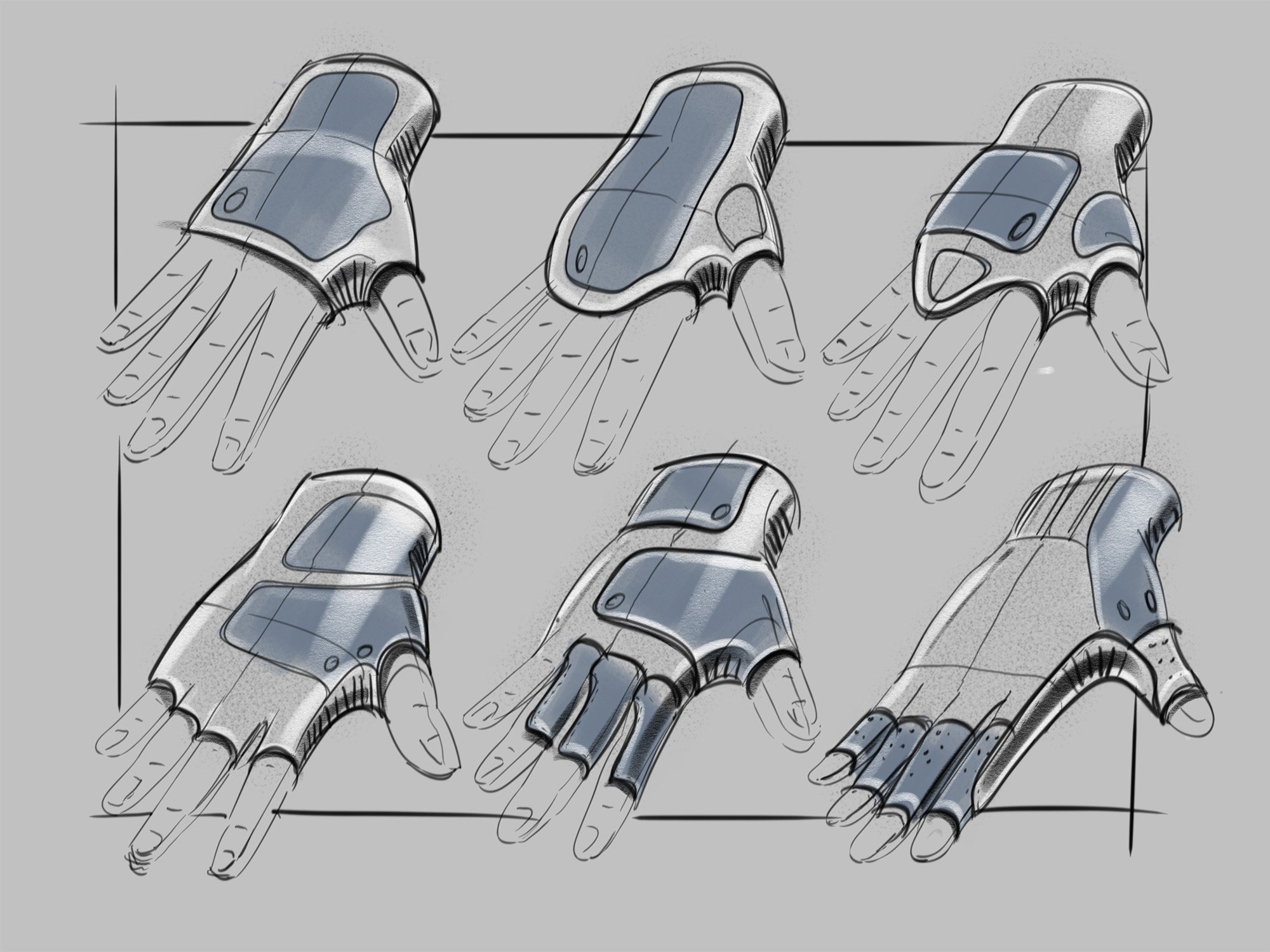

Design Concepts

I was heavily focused on the function and performance possibilities of design as planned in the design brief. The most important key focus is performance and flexibility.

Above diagram is to explore the possibility of an independent sleeve system that may be able to keep both protection and comfortability in check. The interior is a knitting glove piece that has direct injected protection pieces and the face/palm of hand is protected by an independent sleeve that is also directed injected.

I put together a series of hand gear concepts to explore design possibilities. In terms of functionalities of a hand gear key area of protection and performance are re-enforced. The rest of the area are kept clean and simple for maximum comfort and flexibility.

Also color blocking is applied to clearly separate performance areas from the rest surface.

I am not sure if the company move any design into development since it was not part of the project requirement. Plus since I was not able to look into the company’s current injection facility capability. I am not sure if the company is ready to fully utilizing injection moulding in a full production manner.